The Skeleton Paradigm: Thermal Management, Visibility, and the Evolution of Trimmer Design

Update on Dec. 21, 2025, 6:06 p.m.

For decades, the archetype of a hair clipper was a bulky, enclosed plastic brick. The motor, battery, and drive mechanism were hidden away, protected but also suffocated. In recent years, however, a radical shift has occurred in professional grooming tools: the emergence of the “Skeleton” or exposed-blade design.

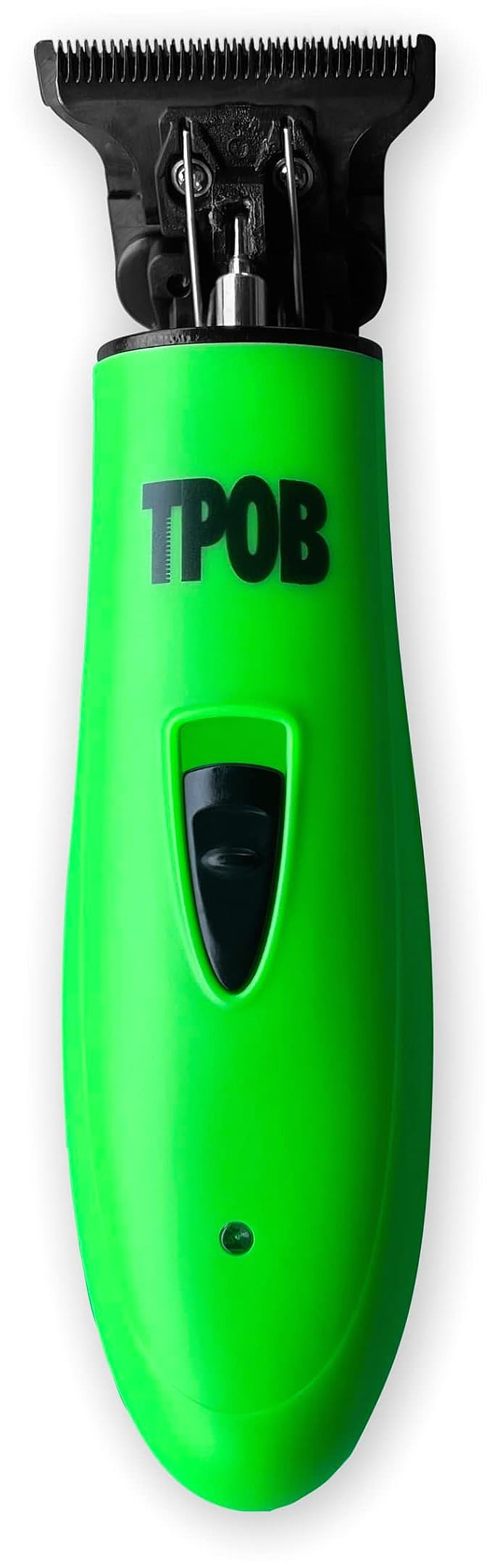

Devices like the TPOB Ghost X are not just styled to look futuristic; they represent a fundamental rethinking of thermal management and visual ergonomics. By removing the housing around the blade drive, engineers have solved two of the most persistent problems in precision grooming: heat buildup and obstructed vision.

Thermal Dynamics: The Problem of Enclosed Heat

Friction generates heat. In a standard trimmer, the metal blades rub against each other thousands of times per minute. In an enclosed housing, this heat—along with the heat from the motor—is trapped. The plastic shell acts as an insulator, creating an oven effect. After 15 minutes of use, the blade can become uncomfortably hot against the skin.

The skeleton design adopts a strategy of passive convection cooling. * Airflow: By exposing the blade assembly and the drive shaft to the open air, heat is dissipated instantly into the environment rather than accumulating in the casing. * Temperature Stability: This “air-cooled” architecture ensures that the blade remains near ambient temperature even during prolonged sessions. For professional barbers or meticulous home users, this means the tool never has to be set down to cool off, protecting the client’s skin from thermal irritation.

Visual Ergonomics: The Line of Sight

Precision trimming—lining up a beard, edging a hairline, or creating hair art—is a geometric task. It requires the user to see exactly where the cutting teeth contact the skin.

Traditional bulky housings create a “blind spot.” The plastic casing overhangs the blade, obscuring the view from certain angles. Users often have to guess the exact cutting line or contort their wrists to get a better view. * 360-Degree Visibility: The skeleton design removes this obstruction entirely. The blade stands alone, separated from the body. This provides a clear, 360-degree line of sight to the cutting edge. * Precision Control: This visibility allows for what engineers call fine motor accuracy. When the eye can see the target without parallax error or obstruction, the hand can guide the tool with sub-millimeter precision. This is why skeleton trimmers are the standard for “lining up” and detailed work.

Maintenance and Hygiene

An exposed design also fundamentally changes the maintenance equation. In enclosed clippers, hair clippings, skin cells, and oil accumulate inside the housing, forming a hidden paste that can jam the motor and breed bacteria.

With a skeleton design like the TPOB Ghost X, there is nowhere for debris to hide. * Blow-Out Capability: A simple blast of air or a brush can instantly clear the entire drive mechanism. * Visual Inspection: The user can see immediately if the drive shaft is wrapped in hair or if the cam follower needs lubrication. This transparency encourages better maintenance habits, which in turn extends the life of the motor and the battery.

Conclusion: Form Follows Function

The skeleton trimmer is a prime example of the design principle “form follows function.” Its stripped-back aesthetic is not just for show; it is the direct result of engineering solutions to heat and visibility. By removing the unnecessary, tools like the TPOB Ghost X enhance the essential: the ability to cut with cool precision and unobstructed vision.